Thyssen & Co. GmbH - a Company in the Course of Time

150 years later, in 2021, Thyssen & Co. GmbH celebrates its 150th anniversary and during this time has developed into a leading global service company. The Group now consists of 24 companies and 11 branches in Germany and abroad.

On April 1, 1871 August Thyssen and his father Friedrich founded Thyssen Compagnie (Thyssen & Co) in Mülheim an der Ruhr. This date was to become the foundation stone for a successful industrial empire. The founding of the German Empire in 1871 released unimagined economic development opportunities.

On April 1, 1871 August Thyssen and his father Friedrich founded Thyssen Compagnie (Thyssen & Co) in Mülheim an der Ruhr. This date was to become the foundation stone for a successful industrial empire. The founding of the German Empire in 1871 released unimagined economic development opportunities.

August Thyssen 17.05.1842 – 04.04.1926, painting by Franz Josef Klemm

August Thyssen 17.05.1842 – 04.04.1926, painting by Franz Josef Klemm

August Thyssen was a brilliant entrepreneur and industrial founder with great foresight and a constant willingness to take risks. He was characterized by the attributes of true entrepreneurship, from prudent caution and sober calculation to creative power and far-sighted daring, plus initiative, problem awareness and an eye for the big picture. On April 1, 1871 he acquired a property in Mülheim-Styrum on which he built a steel strip mill. We know from this that on April 19, 1871 August Thyssen petitioned the Royal District Court in Broich to enter the limited partnership existing since April 1 of the same year under the name Thyssen & Co. with its domicile in Styrum in the rural community of Mülheim an der Ruhr in the Commercial Register.

August Thyssen was a brilliant entrepreneur and industrial founder with great foresight and a constant willingness to take risks. He was characterized by the attributes of true entrepreneurship, from prudent caution and sober calculation to creative power and far-sighted daring, plus initiative, problem awareness and an eye for the big picture. On April 1, 1871 he acquired a property in Mülheim-Styrum on which he built a steel strip mill. We know from this that on April 19, 1871 August Thyssen petitioned the Royal District Court in Broich to enter the limited partnership existing since April 1 of the same year under the name Thyssen & Co. with its domicile in Styrum in the rural community of Mülheim an der Ruhr in the Commercial Register.

Entered in the Commercial Register in 1871 Thyssen & Co. with domicile in Mülheim-Styrum

Entered in the Commercial Register in 1871 Thyssen & Co. with domicile in Mülheim-Styrum

This was the starting position from which August Thyssen developed the important group named after him with widely visible success, the work with which he went down in economic history as a group creator and designer. Finally, in 1871, Gewerkschaft Hamborn, established in Bruckhausen on April 3, 1867, was renamed Gewerkschaft Deutscher Kaiser on November 3, 1871. In the same year this union decided to sink the Deutscher Kaiser 1 shaft, thus laying the foundation stone for Thyssen's mining operations.

This was the starting position from which August Thyssen developed the important group named after him with widely visible success, the work with which he went down in economic history as a group creator and designer. Finally, in 1871, Gewerkschaft Hamborn, established in Bruckhausen on April 3, 1867, was renamed Gewerkschaft Deutscher Kaiser on November 3, 1871. In the same year this union decided to sink the Deutscher Kaiser 1 shaft, thus laying the foundation stone for Thyssen's mining operations.

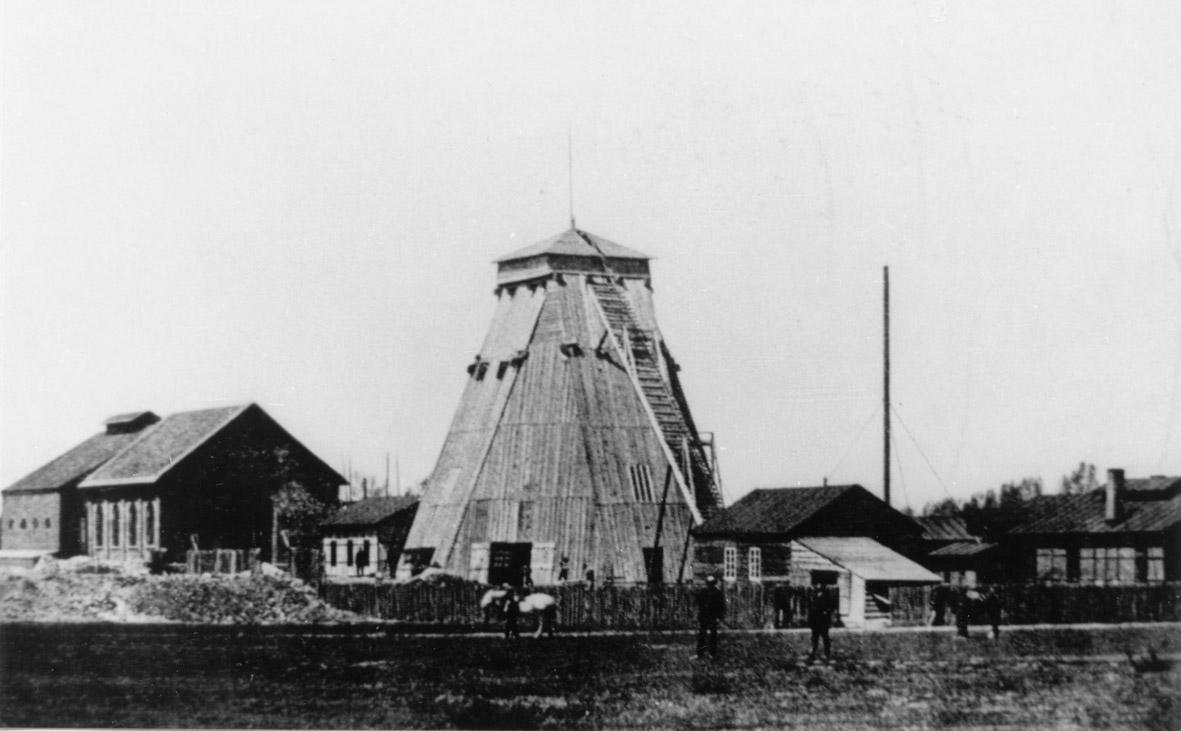

The sinking of shaft 1 of Gewerkschaft Hamborn, which was renamed Gewerkschaft Deutscher Kaiser in the national uproar, was photographed around 1871

The sinking of shaft 1 of Gewerkschaft Hamborn, which was renamed Gewerkschaft Deutscher Kaiser in the national uproar, was photographed around 1871

The beginnings were modest: In 1871 only 70 workers were employed in the forges and rolling mills in Mülheim; welding shops were added later. After the death of his father, August Thyssen entered into a partnership with his younger brother Joseph in 1878.

The beginnings were modest: In 1871 only 70 workers were employed in the forges and rolling mills in Mülheim; welding shops were added later. After the death of his father, August Thyssen entered into a partnership with his younger brother Joseph in 1878.

Joseph Thyssen, 14.02.1844 - 15.07.1915, brother and close confidant of August Thyssen

Joseph Thyssen, 14.02.1844 - 15.07.1915, brother and close confidant of August Thyssen

From 1883 August Thyssen acquired mining shares from the Gewerkschaft Deutscher Kaiser coal mine in Duisburg-Hamborn.

From 1883 August Thyssen acquired mining shares from the Gewerkschaft Deutscher Kaiser coal mine in Duisburg-Hamborn.

In 1891, he finally owned this coal mine outright and formed the starting point for his activities in Ruhr mining. To drive these forward, the specialist department for drilling and shaft sinking was founded in 1898.

In 1891, he finally owned this coal mine outright and formed the starting point for his activities in Ruhr mining. To drive these forward, the specialist department for drilling and shaft sinking was founded in 1898.

Shaft sinking crew of the Deutscher Kaiser 4 shaft in September 1901

Shaft sinking crew of the Deutscher Kaiser 4 shaft in September 1901

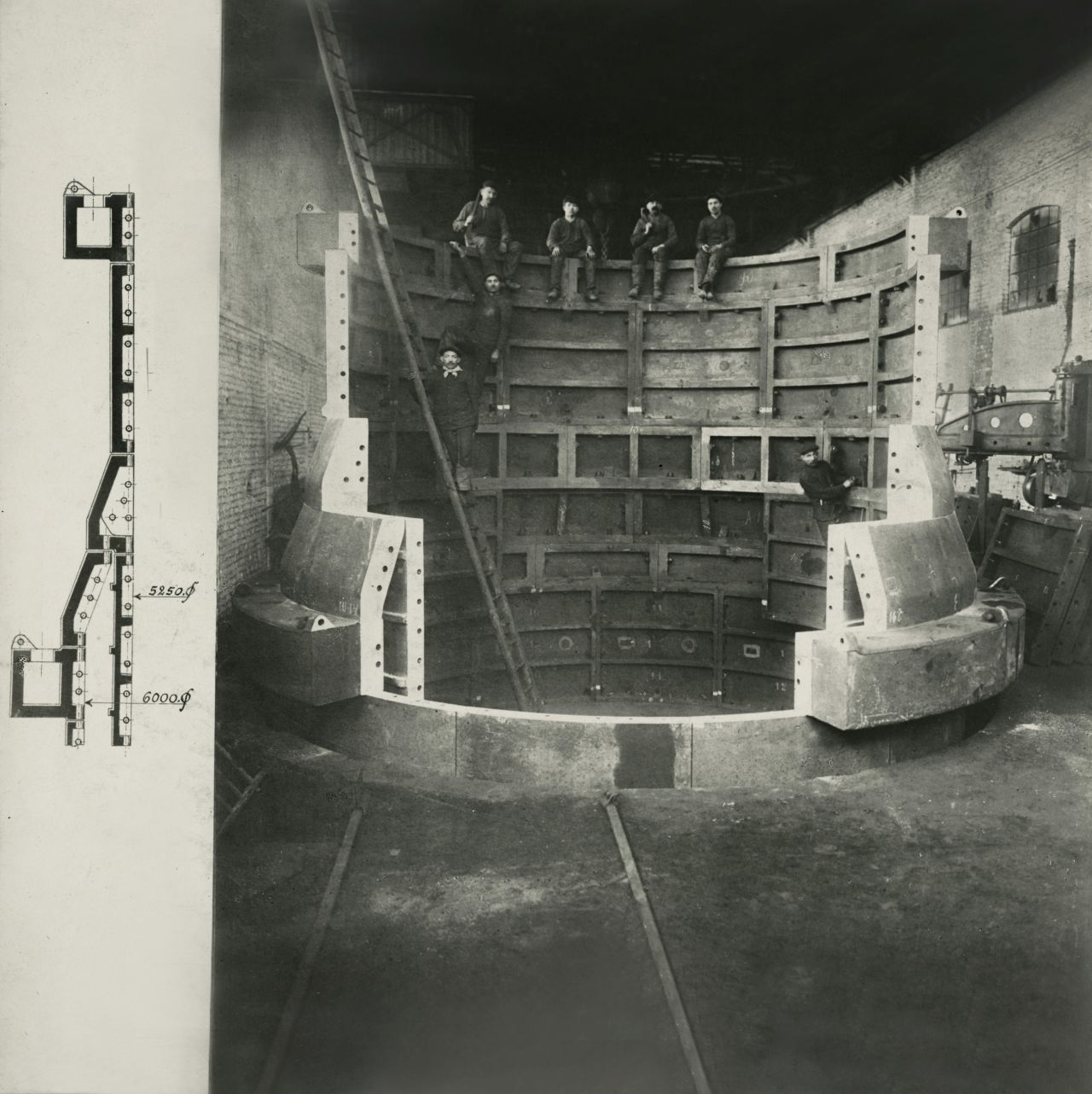

The shaft sinking department of Gewerkschaft Deutscher Kaiser during the sinking of shaft 5, tubbing segment sinking between 1901 and 1909.

The shaft sinking department of Gewerkschaft Deutscher Kaiser during the sinking of shaft 5, tubbing segment sinking between 1901 and 1909.

In 1903 August Thyssen bought Landsberg Castle and moved in there a year later after extensive expansion and renovation work. At the age of 60 he was looking for a new residence. His house in Styrum was by now surrounded by industrial plants. "Landsberg is the only estate you can reach by carriage from Mülheim. Yet it has good forest and water. Its location in the mountains is also desirable to me." In 1926 August Thyssen died at Landsberg at the age of 84. In his will he stipulated that the castle be preserved for his family forever in the form of a foundation. In accordance with the will, his sons established the "August Thyssen Schloss Landsberg Foundation." Built at the end of the 13th century, the castle is located on the present-day city border between Ratingen and Essen. It now serves as a conference and meeting center for the thyssenkrupp group.

In 1903 August Thyssen bought Landsberg Castle and moved in there a year later after extensive expansion and renovation work. At the age of 60 he was looking for a new residence. His house in Styrum was by now surrounded by industrial plants. "Landsberg is the only estate you can reach by carriage from Mülheim. Yet it has good forest and water. Its location in the mountains is also desirable to me." In 1926 August Thyssen died at Landsberg at the age of 84. In his will he stipulated that the castle be preserved for his family forever in the form of a foundation. In accordance with the will, his sons established the "August Thyssen Schloss Landsberg Foundation." Built at the end of the 13th century, the castle is located on the present-day city border between Ratingen and Essen. It now serves as a conference and meeting center for the thyssenkrupp group.

Landsberg Castle from southeast around 1904

Landsberg Castle from southeast around 1904

After the acquisition of Tiefbohr AG Lubisch, the drilling and shaft sinking department was founded in 1905 as an independent company Bohr- und Schachtbau GmbH in Mülheim an der Ruhr, which was dissolved again in 1909 due to changed market conditions and affiliated to Gewerkschaft Deutscher Kaiser as a shaft sinking department.

After the acquisition of Tiefbohr AG Lubisch, the drilling and shaft sinking department was founded in 1905 as an independent company Bohr- und Schachtbau GmbH in Mülheim an der Ruhr, which was dissolved again in 1909 due to changed market conditions and affiliated to Gewerkschaft Deutscher Kaiser as a shaft sinking department.

Forty years have passed and the Mülheim plant has grown into something gigantic: 7,000 workers and 800 employees work here and its products are distributed all over the world.The further development of freezing technology increasingly consolidated the reputation and importance of Thyssen's shaft sinking activities, in particular freeze shaft sinking. Between 1905 and 1911 eleven freeze shafts were built or commissioned. In 1911, the shaft sinking department was awarded its first foreign contract for the construction of two freeze shafts at the Zwartberg double shaft in Belgium. This was followed one year later by an order from the Netherlands to sink the two freeze shafts Oranje-Nassau 3 and 4.

Forty years have passed and the Mülheim plant has grown into something gigantic: 7,000 workers and 800 employees work here and its products are distributed all over the world.The further development of freezing technology increasingly consolidated the reputation and importance of Thyssen's shaft sinking activities, in particular freeze shaft sinking. Between 1905 and 1911 eleven freeze shafts were built or commissioned. In 1911, the shaft sinking department was awarded its first foreign contract for the construction of two freeze shafts at the Zwartberg double shaft in Belgium. This was followed one year later by an order from the Netherlands to sink the two freeze shafts Oranje-Nassau 3 and 4.

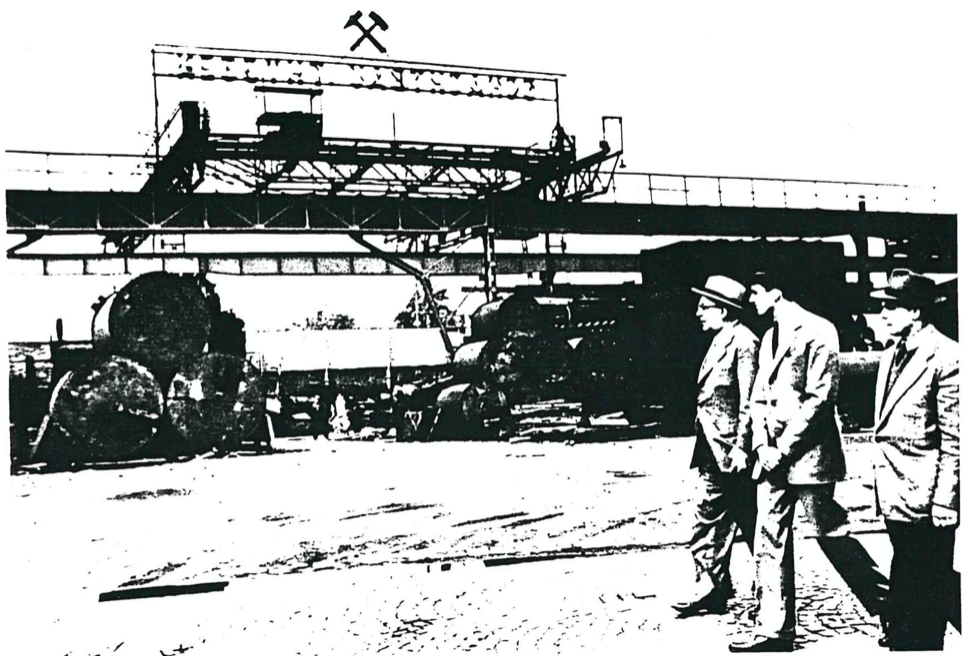

Freezing machines plant Zwartberg in Belgium

Freezing machines plant Zwartberg in Belgium

August Thyssen at Landsberg Castle near Kettwig. This photograph was taken on the occasion of his 70th birthday on May 17, 1912.

August Thyssen at Landsberg Castle near Kettwig. This photograph was taken on the occasion of his 70th birthday on May 17, 1912.

With the end of World War I the Gewerkschaft Deutscher Kaiser was split into the iron and steel division August-Thyssen-Hütte and Gewerkschaft Friedrich Thyssen, in which the mining activities were pooled.

With the end of World War I the Gewerkschaft Deutscher Kaiser was split into the iron and steel division August-Thyssen-Hütte and Gewerkschaft Friedrich Thyssen, in which the mining activities were pooled.

On May 7, 1919 the company Schachtbau Thyssen GmbH was founded with registered office in Mülheim an der Ruhr with a capital stock of 300,000 Reichsmarks. The founders were AG für Hüttenbetriebe, Duisburg-Meiderich, and Thyssen & Co AG, Mülheim an der Ruhr. After August Thyssen's death in 1926 it was mainly his son Fritz Thyssen and the children of his brother Joseph, Julius and Hans, who died in 1915, who determined the fate of the company as owners of Thyssen & Co AG.

On May 7, 1919 the company Schachtbau Thyssen GmbH was founded with registered office in Mülheim an der Ruhr with a capital stock of 300,000 Reichsmarks. The founders were AG für Hüttenbetriebe, Duisburg-Meiderich, and Thyssen & Co AG, Mülheim an der Ruhr. After August Thyssen's death in 1926 it was mainly his son Fritz Thyssen and the children of his brother Joseph, Julius and Hans, who died in 1915, who determined the fate of the company as owners of Thyssen & Co AG.

After the outbreak of war in the fall of 1939 the entire assets of the principal stockholder of Thyssen & Co AG, Fritz Thyssen, were seized and confiscated in favour of the Prussian state. In the absence of a relevant legal title, the seizure of his assets was based at the time on the Law for the Prevention of Communist Activities, which illustrated the wide scope for bending the law in the Third Reich.

After the outbreak of war in the fall of 1939 the entire assets of the principal stockholder of Thyssen & Co AG, Fritz Thyssen, were seized and confiscated in favour of the Prussian state. In the absence of a relevant legal title, the seizure of his assets was based at the time on the Law for the Prevention of Communist Activities, which illustrated the wide scope for bending the law in the Third Reich.

Fritz Thyssen 09.11.1873 – 08.02.1951

Fritz Thyssen 09.11.1873 – 08.02.1951

The collapse in 1945 hit the company particularly hard, with a loss of 45% of its machinery, equipment and facilities and 40% of its buildings. The vacuum in the immediate post-war period also resulted in a reduction of the actual skilled workforce to only 150 men. This was decisively related to the wide dispersion of the workforce, numbering in the thousands, over far-flung objects in the mine. Only some of the miners and their own crews who were obliged to serve in this way returned to their original workplaces, and only after a lengthy postponement.

The collapse in 1945 hit the company particularly hard, with a loss of 45% of its machinery, equipment and facilities and 40% of its buildings. The vacuum in the immediate post-war period also resulted in a reduction of the actual skilled workforce to only 150 men. This was decisively related to the wide dispersion of the workforce, numbering in the thousands, over far-flung objects in the mine. Only some of the miners and their own crews who were obliged to serve in this way returned to their original workplaces, and only after a lengthy postponement.

Workshop in Hamborn at the river Rhine

Workshop in Hamborn at the river Rhine

In this extremely difficult situation Fritz Thyssen initiated proceedings on the basis of Act No. 59 for the restitution of the unjustly expropriated assets - and thus also of the original Schachtbau Thyssen GmbH.

In this extremely difficult situation Fritz Thyssen initiated proceedings on the basis of Act No. 59 for the restitution of the unjustly expropriated assets - and thus also of the original Schachtbau Thyssen GmbH.

Friedrich-Ebert-Street administration building in Mülheim, view after reconstruction and expansion in the 1950s

Friedrich-Ebert-Street administration building in Mülheim, view after reconstruction and expansion in the 1950s

The post-war development, which had begun on ruins, could initially only count on job opportunities in actual mining to a very minor extent. Therefore, it was diverted into non-mining work such as clearing debris, blasting stumps, sealing a dam, construction work for housing, and others. All of these tasks were based on special skills that were familiar from the conventional work of the special mining companies, namely drilling and shooting work, loading work, cementing and bricklaying. In this way, the extremely difficult immediate transitional phase of post-war reconstruction was mastered.

The post-war development, which had begun on ruins, could initially only count on job opportunities in actual mining to a very minor extent. Therefore, it was diverted into non-mining work such as clearing debris, blasting stumps, sealing a dam, construction work for housing, and others. All of these tasks were based on special skills that were familiar from the conventional work of the special mining companies, namely drilling and shooting work, loading work, cementing and bricklaying. In this way, the extremely difficult immediate transitional phase of post-war reconstruction was mastered.

Sandstraße plant site in Mülheim an der Ruhr, storage yard with crane facilities after reconstruction

Sandstraße plant site in Mülheim an der Ruhr, storage yard with crane facilities after reconstruction

This was the first time that Schachtbau Thyssen had tackled and systematically developed the multifaceted field of underground mining long practiced by competing companies. In the industry's parlance, this included the sinking of shafts, the excavation of openings, chambers, roadways and crosscuts, the construction of drifts, openings and stopes as well as hewing and similar work. In the era of Gewerkschaft Deutscher Kaiser, projects of this type were carried out by the mining department's own personnel.

This was the first time that Schachtbau Thyssen had tackled and systematically developed the multifaceted field of underground mining long practiced by competing companies. In the industry's parlance, this included the sinking of shafts, the excavation of openings, chambers, roadways and crosscuts, the construction of drifts, openings and stopes as well as hewing and similar work. In the era of Gewerkschaft Deutscher Kaiser, projects of this type were carried out by the mining department's own personnel.

In view of the close relationship between this underground work and tunnel construction, the latter was also included and sustainably promoted as a promising branch of work. Furthermore, drilling work in the form of surface exploratory boreholes and underground raise and lower boreholes has supplemented the range of tasks. Finally, shaft sinking was placed on a broader footing by extending, converting and repairing shafts. The company was predominantly mining-oriented. In the post-war years, the almost complete abandonment of the construction of new shafts had a particularly inhibiting effect. This was due to the shortage of capital in the West German mining industry and to the fact that North German Coal Control had set its sights on limiting capacity. The company countered this exceptional situation - also in order to increase its resistance to crises - by expanding its work program and by making sustained efforts to operate abroad.

In view of the close relationship between this underground work and tunnel construction, the latter was also included and sustainably promoted as a promising branch of work. Furthermore, drilling work in the form of surface exploratory boreholes and underground raise and lower boreholes has supplemented the range of tasks. Finally, shaft sinking was placed on a broader footing by extending, converting and repairing shafts. The company was predominantly mining-oriented. In the post-war years, the almost complete abandonment of the construction of new shafts had a particularly inhibiting effect. This was due to the shortage of capital in the West German mining industry and to the fact that North German Coal Control had set its sights on limiting capacity. The company countered this exceptional situation - also in order to increase its resistance to crises - by expanding its work program and by making sustained efforts to operate abroad.

To intensify international mining activities, the establishment of a foreign organization was initiated. At the beginning of this process, representative of many other companies and branches abroad which were to follow, Thyssen Shaft Sinking Company Ltd. (later TGB) was founded in May 1954 with a share capital of £2,000.00 in London and Llanelly in Wales.

To intensify international mining activities, the establishment of a foreign organization was initiated. At the beginning of this process, representative of many other companies and branches abroad which were to follow, Thyssen Shaft Sinking Company Ltd. (later TGB) was founded in May 1954 with a share capital of £2,000.00 in London and Llanelly in Wales.

TGB THYSSEN (GREAT BRITAIN) LIMITED, London and Llanelly, Great Britain

TGB THYSSEN (GREAT BRITAIN) LIMITED, London and Llanelly, Great Britain

EMSCHER AUFBEREITUNG GMBH was founded on January 24, 1957 by notarial deed by THYSSEN & Co. AG and SCHACHTBAU THYSSEN GMBH in Duisburg. For more than 60 years, EMSCHER AUFBEREITUNG GMBH has been active in the field of pulverized coal injection (PCI) grinding and drying. Due to the operation of 6 pulverized coal drying plants at the Duisburg plant location, the company has a distinctive knowledge of the manifold process sequences, in particular also in connection with the varying valuable coal and petroleum coke grades.

EMSCHER AUFBEREITUNG GMBH was founded on January 24, 1957 by notarial deed by THYSSEN & Co. AG and SCHACHTBAU THYSSEN GMBH in Duisburg. For more than 60 years, EMSCHER AUFBEREITUNG GMBH has been active in the field of pulverized coal injection (PCI) grinding and drying. Due to the operation of 6 pulverized coal drying plants at the Duisburg plant location, the company has a distinctive knowledge of the manifold process sequences, in particular also in connection with the varying valuable coal and petroleum coke grades.

Foundation of AUG. PAPE GMBH & CO: Today's TS BAU GMBH was formed by merging the companies AUG. PAPE GMBH & Co, BAU-UNION Riesa GmbH & Co, PAPE BAU-UNION GMBH, Proterra GmbH and Thyssen Schachtbau Rohrtechnik GmbH. In 2000, the company was simply renamed TS BAU GMBH. With its current locations in Jena (Thuringia) and Riesa (Saxony), the company has now been in existence since the early 1990s and is active in all the major economic areas of the old and new German states. In addition to turnkey building and industrial construction, the company's range of services includes in particular landfill construction, road, rail and civil engineering, demolition work with rubble recycling, special mining work, pipeline construction, trenchless pipe laying, and water pipeline and sewer rehabilitation using special methods. In the above-mentioned fields, our construction company offers you comprehensive expertise in the execution of all construction projects.

Foundation of AUG. PAPE GMBH & CO: Today's TS BAU GMBH was formed by merging the companies AUG. PAPE GMBH & Co, BAU-UNION Riesa GmbH & Co, PAPE BAU-UNION GMBH, Proterra GmbH and Thyssen Schachtbau Rohrtechnik GmbH. In 2000, the company was simply renamed TS BAU GMBH. With its current locations in Jena (Thuringia) and Riesa (Saxony), the company has now been in existence since the early 1990s and is active in all the major economic areas of the old and new German states. In addition to turnkey building and industrial construction, the company's range of services includes in particular landfill construction, road, rail and civil engineering, demolition work with rubble recycling, special mining work, pipeline construction, trenchless pipe laying, and water pipeline and sewer rehabilitation using special methods. In the above-mentioned fields, our construction company offers you comprehensive expertise in the execution of all construction projects.

Also in 1960, internationalization was advanced with the establishment of THYSSEN MINING CONSTRUCTION OF CANADA LTD in Canada, the first company outside Europe. In the 1960s, the potash industry in Saskatchewan needed expertise to sink shafts through geological formations with extremely high water volumes. The group exported its knowledge to Canada and eventually established Thyssen Mining's headquarters in Regina, Saskatchewan. Nine mine shafts were sunk in the first expansion phase in Canada. From the 1970s to the end of the 20th century, Thyssen Mining Construction Ltd. diversified into a full-service underground mining company in North America. The company became the dominant mining company in the Saskatchewan uranium sector and expanded its operations into both the Canadian and U.S. mining markets.

Also in 1960, internationalization was advanced with the establishment of THYSSEN MINING CONSTRUCTION OF CANADA LTD in Canada, the first company outside Europe. In the 1960s, the potash industry in Saskatchewan needed expertise to sink shafts through geological formations with extremely high water volumes. The group exported its knowledge to Canada and eventually established Thyssen Mining's headquarters in Regina, Saskatchewan. Nine mine shafts were sunk in the first expansion phase in Canada. From the 1970s to the end of the 20th century, Thyssen Mining Construction Ltd. diversified into a full-service underground mining company in North America. The company became the dominant mining company in the Saskatchewan uranium sector and expanded its operations into both the Canadian and U.S. mining markets.

With the foundation of DIG DEUTSCHE INNENBAU GMBH, the aim was to counteract the general downturn in the coal mining industry through increased penetration into other fields of work and to balance sales and earnings by means of diversification. The object of the company when DIG was founded was the planning and execution of interior finishing work, in particular acoustic, plaster and stucco work, combined with the manufacture of partition walls. Due to particularly favorable circumstances, the company immediately had executives and a base of specialists in the new field of interior work.

With the foundation of DIG DEUTSCHE INNENBAU GMBH, the aim was to counteract the general downturn in the coal mining industry through increased penetration into other fields of work and to balance sales and earnings by means of diversification. The object of the company when DIG was founded was the planning and execution of interior finishing work, in particular acoustic, plaster and stucco work, combined with the manufacture of partition walls. Due to particularly favorable circumstances, the company immediately had executives and a base of specialists in the new field of interior work.

Renaming to THYSSEN SCHACHTBAU GMBH: The internationalization and the focus of the company's activities were finally documented once again by the renaming of the company to THYSSEN SCHACHTBAU GMBH.

Renaming to THYSSEN SCHACHTBAU GMBH: The internationalization and the focus of the company's activities were finally documented once again by the renaming of the company to THYSSEN SCHACHTBAU GMBH.

In the 1970s, the development of foreign organizations was continued rapidly with the establishment of new companies and shareholdings in the USA, Australia and Austria. In addition to geographical diversification, this also involved growth- and profit-oriented diversification into other economic sectors. In the course of this development, THYSSEN SCHACHTBAU GMBH was able to achieve a leading position among the specialized mining companies internationally and, moreover, to sustainably strengthen the dimension of its worldwide importance.

In the 1970s, the development of foreign organizations was continued rapidly with the establishment of new companies and shareholdings in the USA, Australia and Austria. In addition to geographical diversification, this also involved growth- and profit-oriented diversification into other economic sectors. In the course of this development, THYSSEN SCHACHTBAU GMBH was able to achieve a leading position among the specialized mining companies internationally and, moreover, to sustainably strengthen the dimension of its worldwide importance.

Head Office Ruhrstraße 1 in Mülheim an der Ruhr from 1976 to 2008

Head Office Ruhrstraße 1 in Mülheim an der Ruhr from 1976 to 2008

A major project for THYSSEN SCHACHTBAU began in 1986 with the sinking of the Gorleben 1 and 2 shafts at the Gorleben exploratory mine until exploratory boreholes were closed off in a manner suitable for final storage. In order to investigate the Gorleben salt dome with regard to its suitability as a repository site for all types of radioactive waste, the Deutsche Gesellschaft zum Bau und Betrieb von Endlagern für Abfallstoffe mbH (DBE), Peine, has been carrying out a geoscientific exploration program since 1979. DBE was commissioned by the Federal Republic of Germany - represented by the Federal Office for Radiation Protection (BfS), Salzgitter - as a so-called third party according to § 9a paragraph 3 Atomic Energy Act with the planning, construction and operation of federal facilities for the final disposal of radioactive waste. After an intensive surface exploration phase, the underground investigation program began with the sinking of the two shafts Gorleben 1 - located about 400 m apart - in the years 1986 to 1997 - and Gorleben 2 - in the years 1989 to 1995. This was followed by the excavation of underground mine workings and the execution of an underground exploration drilling program. In the meantime, the freeze holes of the two shafts have been sealed in a long-term safe manner for a possible repository operation. The sealing of the underground exploratory boreholes in a manner suitable for final storage was the last activity for TS at the Gorleben mine.

A major project for THYSSEN SCHACHTBAU began in 1986 with the sinking of the Gorleben 1 and 2 shafts at the Gorleben exploratory mine until exploratory boreholes were closed off in a manner suitable for final storage. In order to investigate the Gorleben salt dome with regard to its suitability as a repository site for all types of radioactive waste, the Deutsche Gesellschaft zum Bau und Betrieb von Endlagern für Abfallstoffe mbH (DBE), Peine, has been carrying out a geoscientific exploration program since 1979. DBE was commissioned by the Federal Republic of Germany - represented by the Federal Office for Radiation Protection (BfS), Salzgitter - as a so-called third party according to § 9a paragraph 3 Atomic Energy Act with the planning, construction and operation of federal facilities for the final disposal of radioactive waste. After an intensive surface exploration phase, the underground investigation program began with the sinking of the two shafts Gorleben 1 - located about 400 m apart - in the years 1986 to 1997 - and Gorleben 2 - in the years 1989 to 1995. This was followed by the excavation of underground mine workings and the execution of an underground exploration drilling program. In the meantime, the freeze holes of the two shafts have been sealed in a long-term safe manner for a possible repository operation. The sealing of the underground exploratory boreholes in a manner suitable for final storage was the last activity for TS at the Gorleben mine.

Shaft Gorleben 1

Shaft Gorleben 1

As part of the comprehensive and necessary strategic measures within the THYSSEN SCHACHTBAU Group, Maschinentechnik in Mülheim was one of the first operating units to complete its organizational and accounting independence and become market-oriented. The company, which will henceforth operate under the name TS Technologie + Service GmbH, has created the basis for positive business development with its expanded external customer base. The new company's task was to realign its business and market strategy. The numerous service spectrums such as pipe and plant construction, repair, machining, assembly, crane and gate technology, electrical engineering and engineering are available as individual or complete solutions. The company manufactures a wide range of steel structures, plant components and machinery for customers in the power plant and metallurgical engineering, mechanical engineering, mining and quarrying industries, among others. High-performance machinery on a production area of around 7,600 m² with crane capacities for unit weights of up to 100 t enables the production of voluminous and heavy structures.

As part of the comprehensive and necessary strategic measures within the THYSSEN SCHACHTBAU Group, Maschinentechnik in Mülheim was one of the first operating units to complete its organizational and accounting independence and become market-oriented. The company, which will henceforth operate under the name TS Technologie + Service GmbH, has created the basis for positive business development with its expanded external customer base. The new company's task was to realign its business and market strategy. The numerous service spectrums such as pipe and plant construction, repair, machining, assembly, crane and gate technology, electrical engineering and engineering are available as individual or complete solutions. The company manufactures a wide range of steel structures, plant components and machinery for customers in the power plant and metallurgical engineering, mechanical engineering, mining and quarrying industries, among others. High-performance machinery on a production area of around 7,600 m² with crane capacities for unit weights of up to 100 t enables the production of voluminous and heavy structures.

The year 2004 was to be another milestone in the economic history of the Group: A strategic decision was taken to enter the Russian mining market. Russia is not only the largest and most resource-rich country on earth, it is also one of the world's biggest growth markets. The country's ambitious goal of doubling its economic output within the next eight to ten years also opened up promising prospects for foreign companies. In order to be able to participate in this growth-oriented and, from an entrepreneurial point of view, promising Russian market, THYSSEN SCHACHTBAU GMBH established a representative office in Moscow in 2004 as an entry point and in preparation for future economic activities. The representative office is intended to make a lasting contribution to facilitating and intensifying contact with the Russian business community. For the mutual improvement of the business activities the companies Shakhtspetsstroi and THYSSEN SCHACHTBAU GMBH concluded a cooperation agreement in 2004. After further approximation of the business relations the common activities are to be extended step by step.

The year 2004 was to be another milestone in the economic history of the Group: A strategic decision was taken to enter the Russian mining market. Russia is not only the largest and most resource-rich country on earth, it is also one of the world's biggest growth markets. The country's ambitious goal of doubling its economic output within the next eight to ten years also opened up promising prospects for foreign companies. In order to be able to participate in this growth-oriented and, from an entrepreneurial point of view, promising Russian market, THYSSEN SCHACHTBAU GMBH established a representative office in Moscow in 2004 as an entry point and in preparation for future economic activities. The representative office is intended to make a lasting contribution to facilitating and intensifying contact with the Russian business community. For the mutual improvement of the business activities the companies Shakhtspetsstroi and THYSSEN SCHACHTBAU GMBH concluded a cooperation agreement in 2004. After further approximation of the business relations the common activities are to be extended step by step.

Activities in Russia and Kasakhstan

Activities in Russia and Kasakhstan

Shaft sinking north of the Arctic Circle: After a three-year bidding and negotiation phase, THYSSEN SCHACHTBAU GMBH was awarded a contract in September 2007 by OJSC MMC NORILSK NICKEL (MMC Norilsk Nickel) for "Design, construction and installation of the shaft object complex WS-10 ventilation shaft, Skalistij mine" for the ore mining combine in Norilsk on the Taimyr Peninsula, a Siberian region north of the Arctic Circle. The Norilsk mining district is located in central Siberia in the Arctic Circle region, east of the Yenisey River. In these latitudes, the permafrost thaws to a maximum depth of 6 meters for a short time only during the two summer months due to the constantly prevailing, extremely icy temperatures. The Norilsk mining region is home to very rich ore bodies, from which mainly nickel, copper and platinum are extracted. The WS-10 ventilation shaft is also planned above a very rich ore body and is part of the new "Skalistij" mine complex to be opened up, whose deposit will secure ore production from the Norilsk mining region for decades from the end of 2015. Work on sinking the SKS-1 production shaft, which is positioned around 1,500 meters adjacent to the WS-10 site, is also scheduled to start in the near future. Here, too, we were awarded the contract. The contract volume, which was awarded to THYSSEN SCHACHTBAU GMBH as general contractor, ultimately comprises the construction of two complete mine installations. These two orders were to become the start of extensive follow-up contracts with well-known customers in the raw materials industry in the Russian Federation.

Shaft sinking north of the Arctic Circle: After a three-year bidding and negotiation phase, THYSSEN SCHACHTBAU GMBH was awarded a contract in September 2007 by OJSC MMC NORILSK NICKEL (MMC Norilsk Nickel) for "Design, construction and installation of the shaft object complex WS-10 ventilation shaft, Skalistij mine" for the ore mining combine in Norilsk on the Taimyr Peninsula, a Siberian region north of the Arctic Circle. The Norilsk mining district is located in central Siberia in the Arctic Circle region, east of the Yenisey River. In these latitudes, the permafrost thaws to a maximum depth of 6 meters for a short time only during the two summer months due to the constantly prevailing, extremely icy temperatures. The Norilsk mining region is home to very rich ore bodies, from which mainly nickel, copper and platinum are extracted. The WS-10 ventilation shaft is also planned above a very rich ore body and is part of the new "Skalistij" mine complex to be opened up, whose deposit will secure ore production from the Norilsk mining region for decades from the end of 2015. Work on sinking the SKS-1 production shaft, which is positioned around 1,500 meters adjacent to the WS-10 site, is also scheduled to start in the near future. Here, too, we were awarded the contract. The contract volume, which was awarded to THYSSEN SCHACHTBAU GMBH as general contractor, ultimately comprises the construction of two complete mine installations. These two orders were to become the start of extensive follow-up contracts with well-known customers in the raw materials industry in the Russian Federation.

WS-10 mine and SKS-1 mine in the background in Norilsk, Siberia

WS-10 mine and SKS-1 mine in the background in Norilsk, Siberia

OOO Thyssen Mining Construction East was founded in 2008 as the company's first subsidiary in Russia. TMCE was initially mainly responsible for the import and export of machinery and equipment. In the meantime the company carries out a wide range of mining work in Russia independently.

OOO Thyssen Mining Construction East was founded in 2008 as the company's first subsidiary in Russia. TMCE was initially mainly responsible for the import and export of machinery and equipment. In the meantime the company carries out a wide range of mining work in Russia independently.

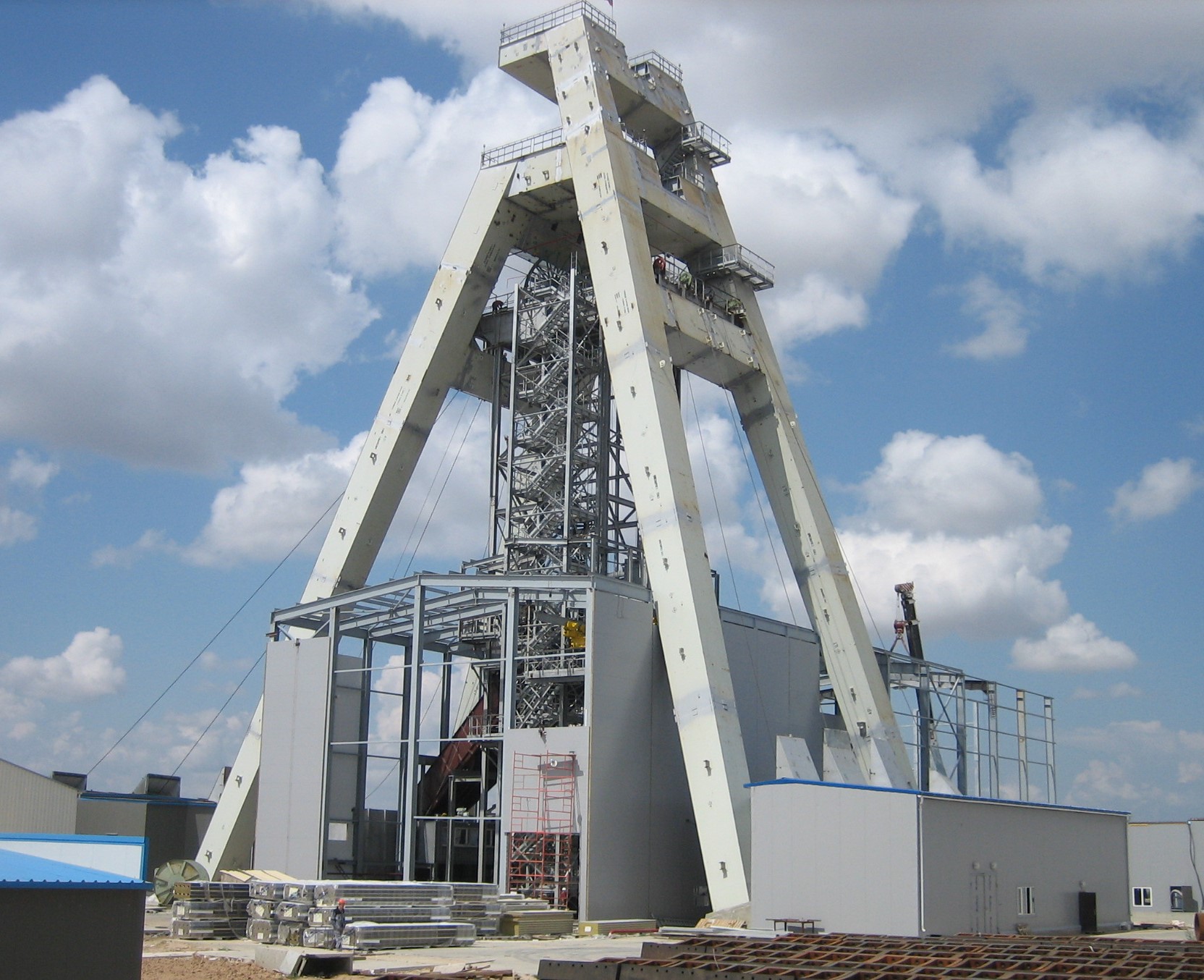

Sinking of the first freeze shaft "Gremjatschinskij" for EuroChem: The Russian mineral and chemical company MCC EuroChem OJSC from Moscow has commissioned THYSSEN SCHACHTBAU GMBH with the sinking of the approx. 1,180 m deep production shaft of the "Gremjatschinskij potash deposit" on May 29, 2008. The potash salt mine of the "Gremjatschinskij Deposit" is located in the Kotelnikovo district of the Volgograd region in Russia, approx. 170 km southwest of the city of Volgograd and approx. 20 km northeast of the regional center of Kotelnikovo. The mine facilities are expected to have a future production capacity of 2.3 million tons of potassium chloride per year. Potash is an extremely important and strategic raw material. Productivity will also have to be increased worldwide in the coming years in order to meet demand, especially for agricultural products.

Sinking of the first freeze shaft "Gremjatschinskij" for EuroChem: The Russian mineral and chemical company MCC EuroChem OJSC from Moscow has commissioned THYSSEN SCHACHTBAU GMBH with the sinking of the approx. 1,180 m deep production shaft of the "Gremjatschinskij potash deposit" on May 29, 2008. The potash salt mine of the "Gremjatschinskij Deposit" is located in the Kotelnikovo district of the Volgograd region in Russia, approx. 170 km southwest of the city of Volgograd and approx. 20 km northeast of the regional center of Kotelnikovo. The mine facilities are expected to have a future production capacity of 2.3 million tons of potassium chloride per year. Potash is an extremely important and strategic raw material. Productivity will also have to be increased worldwide in the coming years in order to meet demand, especially for agricultural products.

Winding tower at the Gremjatschinskij freeze shaft

Winding tower at the Gremjatschinskij freeze shaft

Purchase of TOO SCHACHTBAU Kasachstan in Chromtau: The aim was to offer mining special services of all kinds in Kazakhstan together with our partner SCHACHTBAU NORDHAUSEN GmbH. The focus of the planned services is on shaft sinking, lining and reconstruction. In addition, other projects such as roadway drivages and cross-cuts are also to be highlighted as core tasks.

Purchase of TOO SCHACHTBAU Kasachstan in Chromtau: The aim was to offer mining special services of all kinds in Kazakhstan together with our partner SCHACHTBAU NORDHAUSEN GmbH. The focus of the planned services is on shaft sinking, lining and reconstruction. In addition, other projects such as roadway drivages and cross-cuts are also to be highlighted as core tasks.

Roadway drivage for the world's largest ferrochrome producer Donskoy GOK in Chromtau

Roadway drivage for the world's largest ferrochrome producer Donskoy GOK in Chromtau

Purchase of OLKO-Maschinentechnik GmbH: Since the company was founded in 1989, OLKO-Maschinentechnik has been one of the driving forces in the shaft sinking and hoisting technology segment. OLKO-Maschinentechnik is mainly active in the field of heavy machinery construction for mining companies and special machinery construction both nationally and internationally. Furthermore, the company is a leader in the construction of hoisting machines and sinking winches as well as in building materials technology. The strategic approach for the acquisition of the company was to be able to offer all mining activities in the Group from "one" source in the future. The development of our own products (e.g. car shaft winch, pontoon dredger, hoisting machine brake) has also enabled us to gain access to international markets such as China, Turkmenistan, Russia and the USA.

Purchase of OLKO-Maschinentechnik GmbH: Since the company was founded in 1989, OLKO-Maschinentechnik has been one of the driving forces in the shaft sinking and hoisting technology segment. OLKO-Maschinentechnik is mainly active in the field of heavy machinery construction for mining companies and special machinery construction both nationally and internationally. Furthermore, the company is a leader in the construction of hoisting machines and sinking winches as well as in building materials technology. The strategic approach for the acquisition of the company was to be able to offer all mining activities in the Group from "one" source in the future. The development of our own products (e.g. car shaft winch, pontoon dredger, hoisting machine brake) has also enabled us to gain access to international markets such as China, Turkmenistan, Russia and the USA.

OOO Thyssen Schachtbau EuroChem Bohren, TEB, Kotelnikovo: The company was established jointly with EuroChem to carry out all drilling projects for EuroChem in Russia.

OOO Thyssen Schachtbau EuroChem Bohren, TEB, Kotelnikovo: The company was established jointly with EuroChem to carry out all drilling projects for EuroChem in Russia.

Drilling in the Saratov region on the border with Kazakhstan

Drilling in the Saratov region on the border with Kazakhstan

THYSSEN SCHACHTBAU HOLDING GMBH manages and coordinates the business activities of the THYSSEN SCHACHTBAU Corporation in Germany and abroad with its central service functions such as finance and accounting, human resources, IT, purchasing, controlling, legal and organization. Today, the corporation is divided into the four business segments Mining Technology, Construction, Production and Facility Management and currently employs more than 2,200 people. Today, the traditional company is still family-owned with Claudio L. Count Zichy-Thyssen as Chairman of the Supervisory Board of THYSSEN SCHACHTBAU.

THYSSEN SCHACHTBAU HOLDING GMBH manages and coordinates the business activities of the THYSSEN SCHACHTBAU Corporation in Germany and abroad with its central service functions such as finance and accounting, human resources, IT, purchasing, controlling, legal and organization. Today, the corporation is divided into the four business segments Mining Technology, Construction, Production and Facility Management and currently employs more than 2,200 people. Today, the traditional company is still family-owned with Claudio L. Count Zichy-Thyssen as Chairman of the Supervisory Board of THYSSEN SCHACHTBAU.

Claudio L. Graf Zichy-Thyssen

Claudio L. Graf Zichy-Thyssen

The management of the Thyssen & Co. Corporation is in the hands of Group President Michael Klein.

The management of the Thyssen & Co. Corporation is in the hands of Group President Michael Klein.

Dipl.-Kfm. Michael Klein

Dipl.-Kfm. Michael Klein

Further interesting orders at home and abroad are to follow in the next decades. The aim is to continue to operate on the market with full commitment and with success. Miners are used to mastering change and accepting new challenges. Geology demands these qualities on a daily basis and has left a lasting mark on our actions accordingly. We are used to dealing with difficult situations and finding new solutions. This has been true for the last 150 years and will continue to be true in the future.

Further interesting orders at home and abroad are to follow in the next decades. The aim is to continue to operate on the market with full commitment and with success. Miners are used to mastering change and accepting new challenges. Geology demands these qualities on a daily basis and has left a lasting mark on our actions accordingly. We are used to dealing with difficult situations and finding new solutions. This has been true for the last 150 years and will continue to be true in the future.

Today's headquarters on Sandstrasse in Mülheim an der Ruhr

Today's headquarters on Sandstrasse in Mülheim an der Ruhr